Manuals

System Platform 1 Book A

| Lab 01 - Creating the Galaxy Create a Galaxy and connect to it using Archestra IDE. |

| Lab 02 - Creating Global Derived Templates Derived template, template toolsets, hide base templates, . |

| Lab 03 - Creating and Plant and Deployment Models Plant model, Model View, deployment model, $AppEngine, deployment view. |

| Lab 04 - Using Object Viewer Object viewer diagnostic tool, test application objects, modify values, watch lists, add watch list attributes. |

| Lab 05 - Configuring for Data Simulation Configure an instance for $OPCClient, activate OI.SIM Simulator, connect OPC client to OI.SIM, monitor with object viewer. |

| Lab 06 - Modeling Meters Configure and use object templates including inherited configs, application objects, acquire data from the OI Simulator, monitor in Object Viewer. |

| Lab 07 - Configuring Change Control and Propagation Lock attributes to control changes, propagate changes from template in support of establishing standards. |

| Lab 08 - Modeling the Mixer Configure analog and discrete IO, contained $UserDefined objects, IO binding, simulator object. |

| Lab 09 - Configuring the OI Server Operations Integration Server Manager in the SMC, Modbus OI Server, PLC simulator, import aliases through csv. |

| Lab 10 - Configuring the Device Integration Object Configure $gDDESuiteLinkClient, OI Server, SuiteLink protocol, monitor connection with Object Viewer. |

| Lab 11 - Connecting the Mixer to the Field Production Area, change IO assignment, connect objects to live controller data, monitor data acquisition. |

| Lab 12 - Configuring the Redundant DI Object Configure Galaxy for redundancy at device integration level by using Redundant DI Object monitoring two DI objects. |

| Lab 13 - Configuring and Retrieving History Configure Galaxy for Historization to the Process Historian Server, configure AppEngine Object to store historical data to Process Historian. |

| Lab 14 - Configuring and Interacting with Alarms Hi and Lo level alarms, monitor alarm attribute, triggered from PLC, interact with alarm attributes, use Insignt and MS SQL Management Studio. |

| Lab 15 - Exporting and Importing Objects Export and Import Object features of Archestra to upgrade and downgrade object versions. Make copies of objects within the Galaxy. |

| Lab 16 - Configuring Instances Using a CSV File Galaxy Dump and Load features to change configuration including contained objects. Load feature to create new mixer from existing csv. |

| Lab 17 - Configuring Security Enable security in the Galaxy to use operating system user groups (OS Groups) as an authentication method. |

| Lab 18 - Implementing Object Security Configure security classifications in some automation objects. For example, the valve cmd attribute has an operate security classification by default. |

| Lab 19 - Adding Auto Reconnect to the DDESuiteLinkClient Object Configure $gDDESuiteLinkClient to automatically reconnect to the data source when the connection is lost. |

| Lab 20 - Scripting Value Status Add a script to the $Valve template to report all of the stages of the valve: Open, Close, and Traveling. Done using an array attribute. |

| Lab 21 - Scripting Custom Alarms Configure two new attributes with alarm features to monitor the flow to the transfer pumps within $Mixer template Ad a script to monitor the same and trigger an alarm. |

| Module 11 - Galaxy Backup and Restore Describe the SMC and explain how to back up and restore operations using Galaxy Database manager. Create a new Galaxy from a backup file |

System Platform 1 Book B

| Lab 01 - Creating and Deploying the Galaxy Create and connect to Galaxy, import objects, configure for multi-node configuration, deploy. |

| Lab 02 - Creating a Managed InTouch Application Create a simple Managed InTouch application using $InTouchViewApp template (Window Maker). |

| Lab 03 - Building the Application Layout Create windows for Managed InTouch app, navigation, alarm display, overview display, content display. |

| Lab 04 - Deploying an InTouch Application Deploy a Managed InTouch application. |

| Lab 05 - Building a Process Overview Use Symbol Editor to create a new Archestra symbol in graphics toolbox, embed Situational Awareness dashboard symbols. |

| Lab 06 - Creating the Mixer Components Create mixer components from Situational Awareness library.. |

| Lab 07 - Creating the Mixer Display Embed sysbols in a containment relationship, build a master display containing these displays. |

| Lab 08 - Switching Between Mixers Add a Combo Box to switch between mixers, Add the Owning Object property to the mixers to enable switching. |

| Lab 09 - Creating a Custom Symbol Create custom symbols for use in a command panel for actuation.. |

| Lab - 10 Creating a Navigation Symbol Create a navigation symbol that will switch displays. |

| Lab 11 Applying Alarm Boarder Animation Enable the alarm boarder wizard.. |

| Lab 12 - Building an Alarm Aggregation Overview Build an alarm aggregation overview symbol which will display alarm information. |

| Lab 13 - Building a Live Alarm Display Use the Alarm Content control to display live alarms. |

| Lab 14 - Creating an Alarm Popup Symbol Create alarm displays tied to specific equipment. Use scripting to build alarm queries. |

| Lab 15 - Building a Historical Alarm Display Use Alarm Client to create an alarm display for visualization of historical alarms and events. |

| Lab 16 - Adding Trending to Graphics |

| Lab 17 - Creating a Trend Popup Symbol |

| Lab 18 - Building a Historical Trend Display |

| Lab 19 - Using Security Features in Graphics Create a symbol to add built-in login and logout capabilities triggered from the symbol. |

| Lab 20 - Singing Writes from InTouch Test the InTouchSecured Write and Verified Write functions when writing to attributes configured with these functions. |

| Lab 21 - Locking Down Your Application Configure your application for user inactivity. |

| Lab 22 - Using the Web Client Enable Web Client Server, set the home folder and home symbol, fast switch between preview and navigation and display in browser. |

InTouch

| Lab 01 - Creating the Modern InTouch Application Using the InTouch Application Manager. |

| Lab 02 - Setting Up Windows and Navigation Create windows in WindowMaker, layouts. |

| Lab 03 - Defining Memory Tags Working with memory variables. |

| Lab 04 - Configuring the IO Server Configure an OI Server named MBTCP, connect to Modbus simulator. |

| Lab 05 - Creating IO Access Tags Create an access name to connect to OI server. |

| Lab 06 - Watching Tags with Tag Viewer Use Tag Viewer to monitor IO data and communications. |

| Lab 07 - Exporting and Importing Tags Use DBDump utility to export all tags. |

| Lab 08 - Building a Dashboard Add two Situational Awareness library dashboard symbols then configure the wizard options. |

| Lab 09 - Building the Mixer Operational Display Design a mixer symbol using the Situational Awareness library graphics. |

| Lab 10 - Building a Process Overview Combine the existing Mixer graphic to form a Tank Farm graphic. |

| Lab 11 - Configuring InTouch Alarms Configure alarm limits for InTouch tags, use Situational Awareness Wizard options. |

| Lab 12 - Visualizing and Acknowledging Live Alarms Create a symbol and embed and configure a .NET Alarm Client. |

| Lab 13 - Visualizing and Filtering Historical Alarms and Events Descriptive text. |

| Lab 14 - Logging Historical Data using InTouch History Configure the application to begin historical logging as well as configure the tags which will log data. |

| Lab 15 - Trending Real-Time Data Create a real-time trend symbol and embed a .NET Trend Client control, configure the trend client to display tags in real time. |

| Lab 16 - Logging Historical Data using Historian Descriptive text. |

| Lab 17 - Building a Historian Client Trend Display Use the Historian Client Trend .NET control to create a display for tag data from Historian Server in a Trend chart. |

| Lab 18 - Application-Wide Scripting Experience the key script and the data change script. |

| Lab 19 - Creating an Agitator Timer Create an agitator timer to monitor the run-time period of the agitator. |

| Lab 20 - Creating a Scalable Window Navigation Control Navigate between different windows. |

| Lab 21 - Building a Mixer Browser Using ShowGraphic Build a mixer browser using advanced features of ShowGraphic. |

| Lab 22 - Setting up and Using OS Security Setup operating system security in InTouch, Active Directory. |

| Lab 23 - Locking Down Your Application Secure your application from unauthorized access. |

| Lab 24 - Backing Up and Restoring a Modern InTouch Application |

| Lab 25 - Distributing An InTouch Application Configure Network Application Development (NAD) to copy your application to a product node. |

| InTouch QuickScripts |

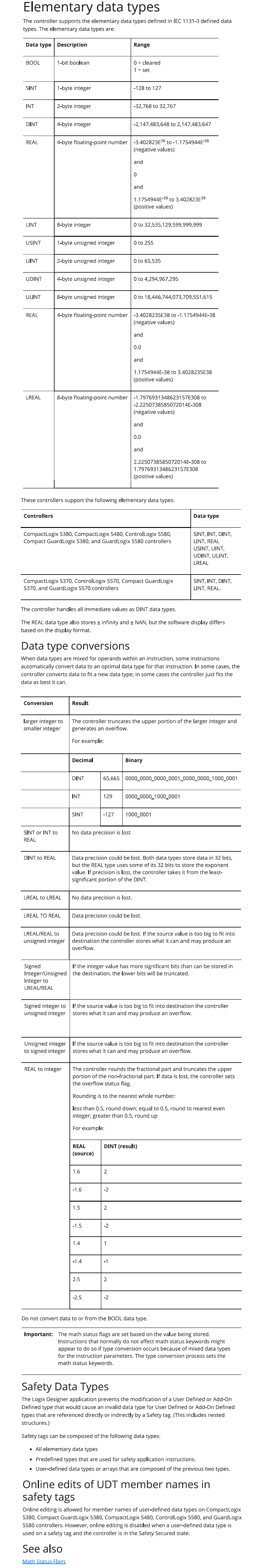

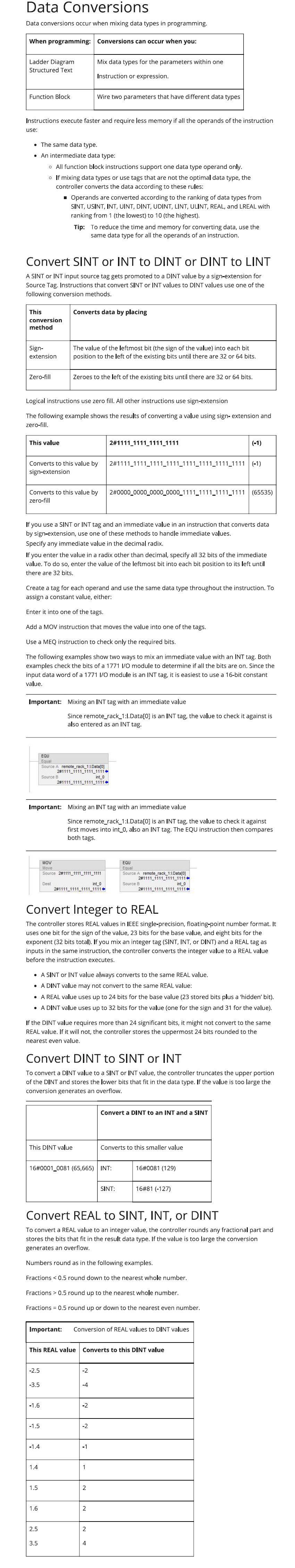

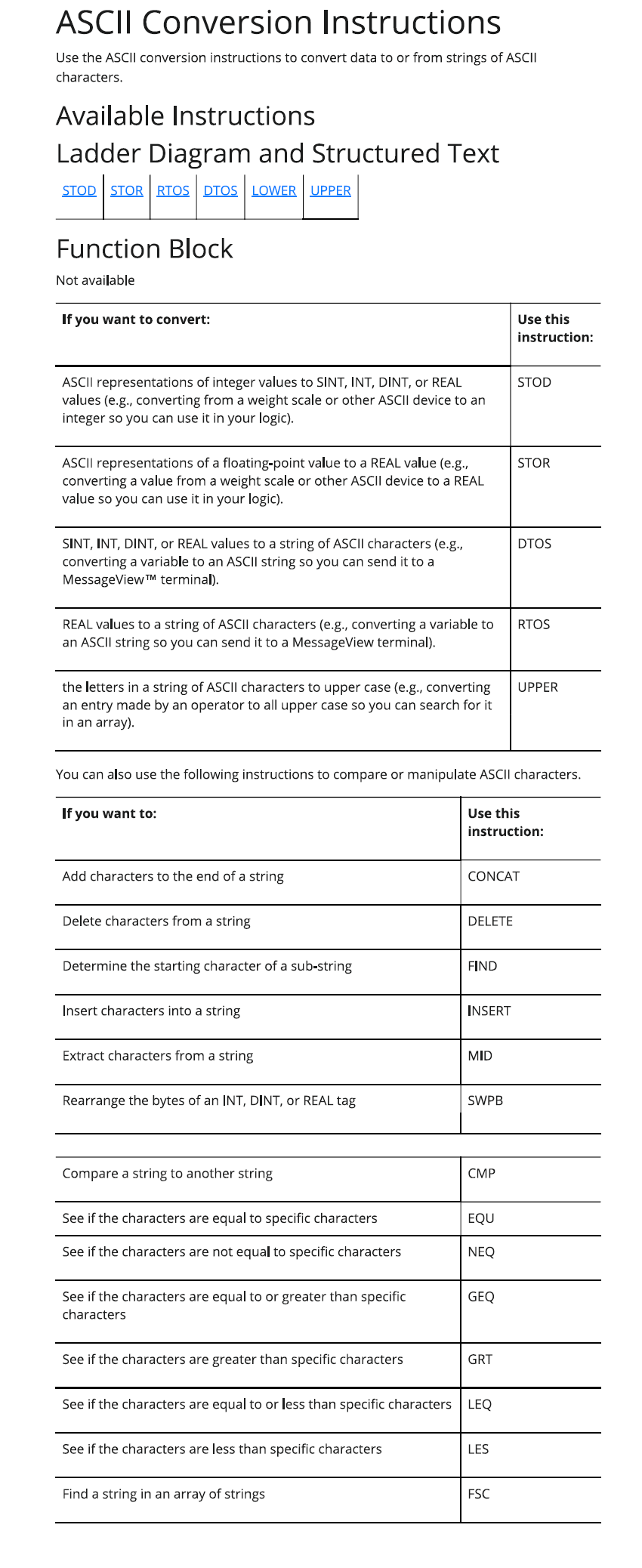

| Elementary Data Types | Data Conversions | ASCII Conversion Instructions | DINT to String |

| String to DINT | Real to String | String to Real | Lower Case |

| Upper Case |

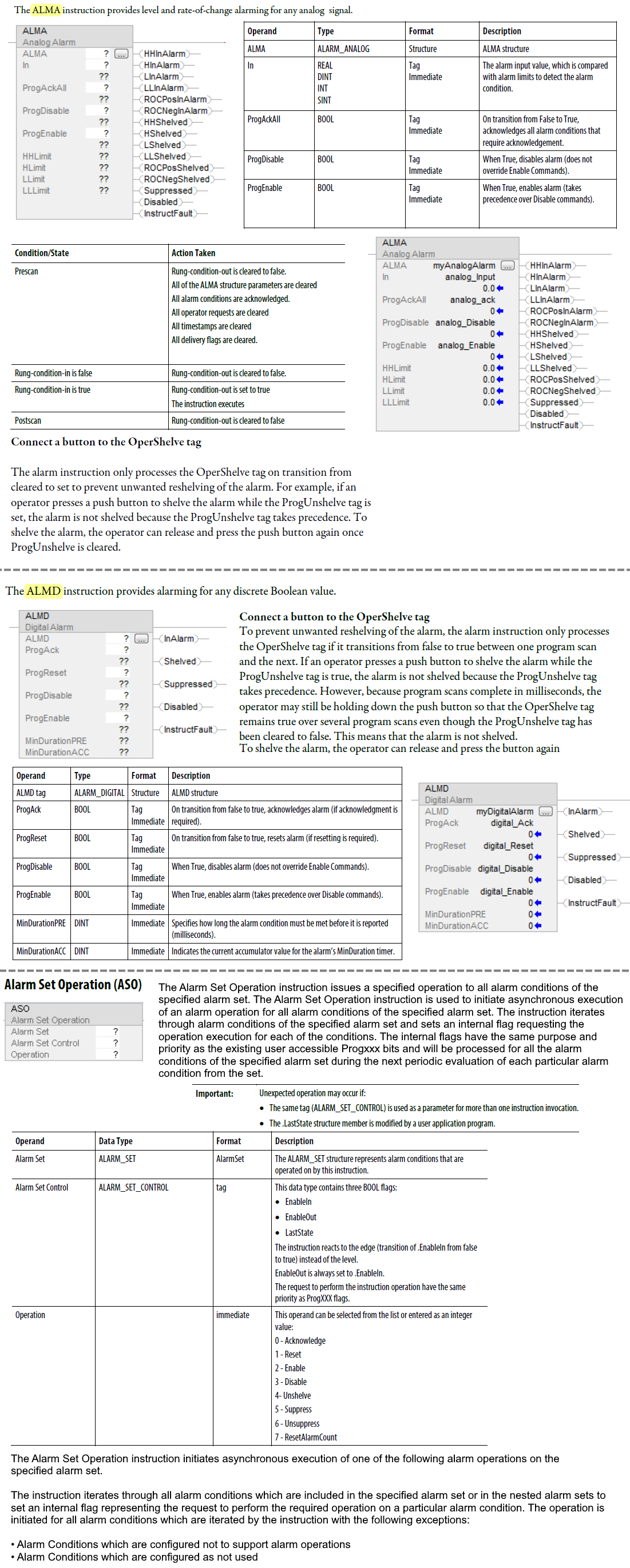

| Alarm Instructions | Alarm Set Operation ASO | Analog Alarm ALMA |

.png)

.png)

.png)

.png)

.png)

.png)

, Shift Instructions.png)

,Misc Instructions.png)

.png)

.png)

, Synchronous Copy File (CPS).png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

Parts

Parts

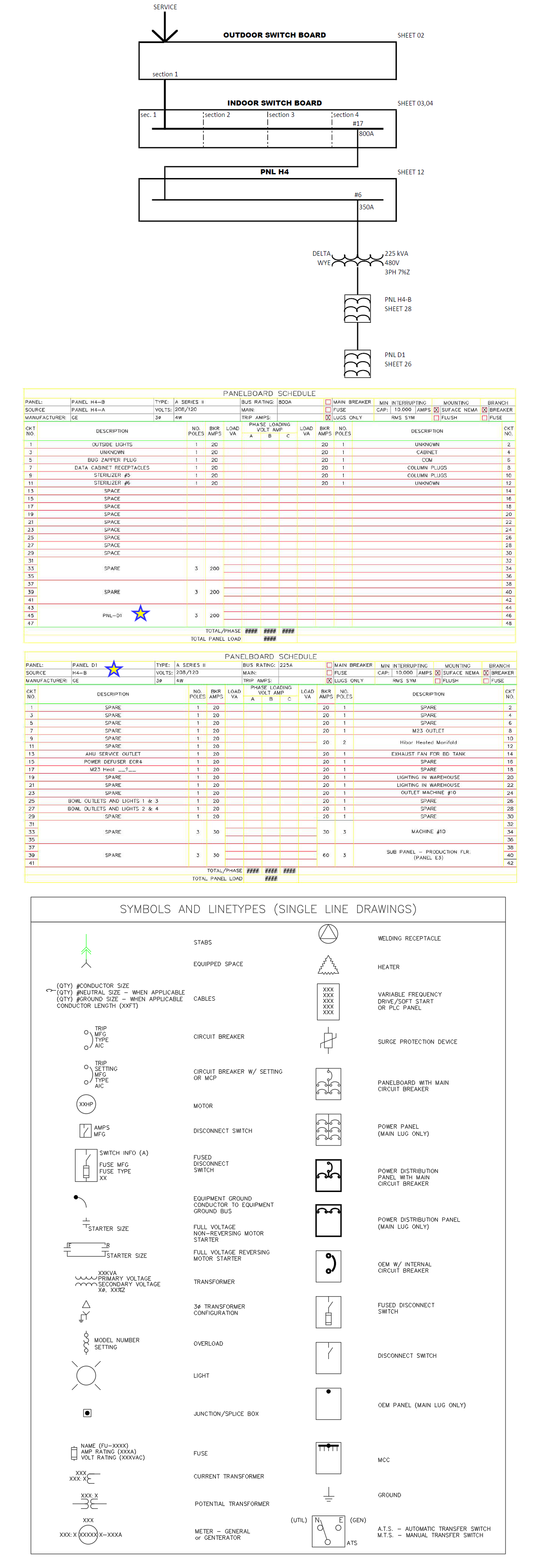

Parker product family fact sheet poster

Parker product family fact sheet poster

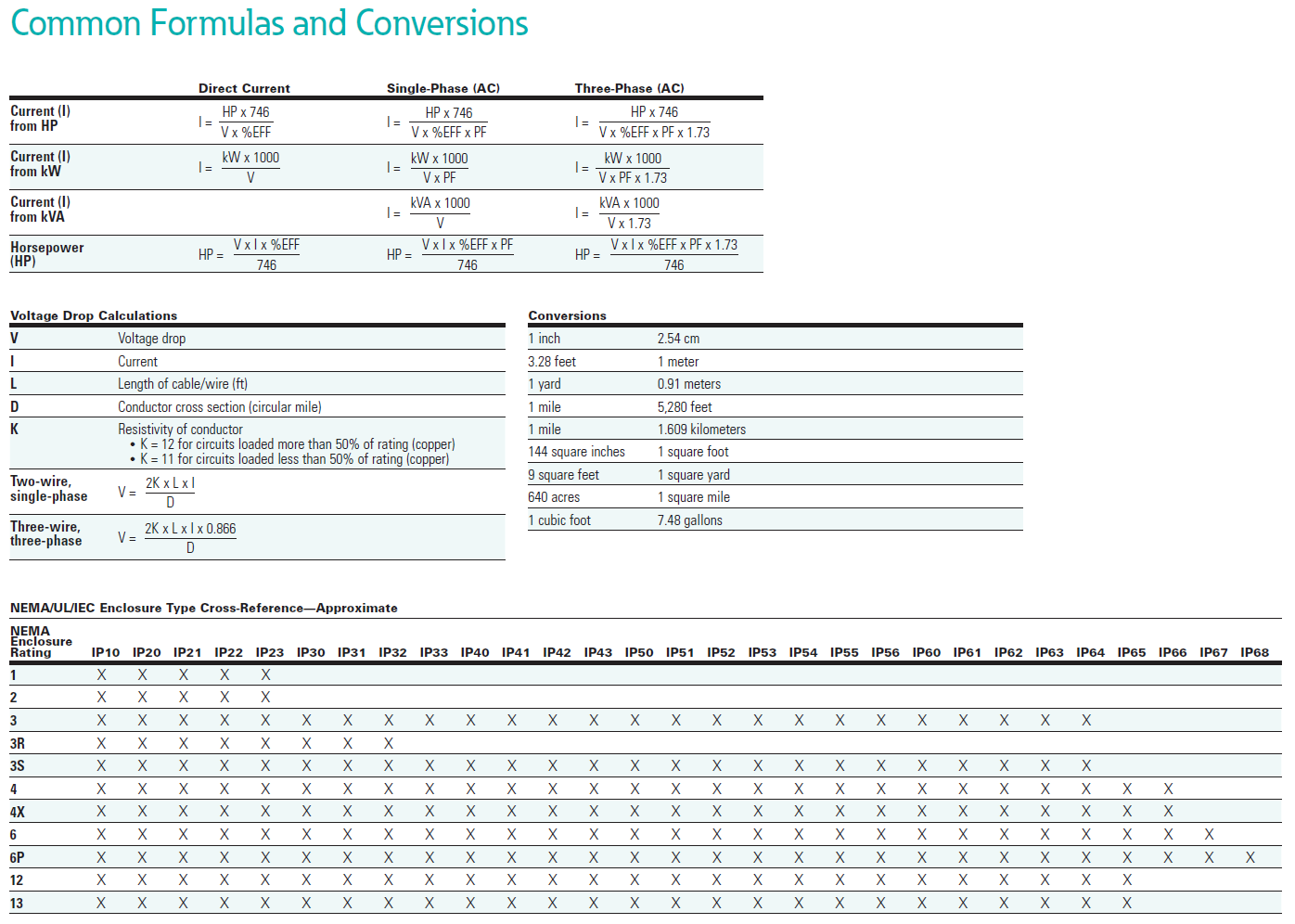

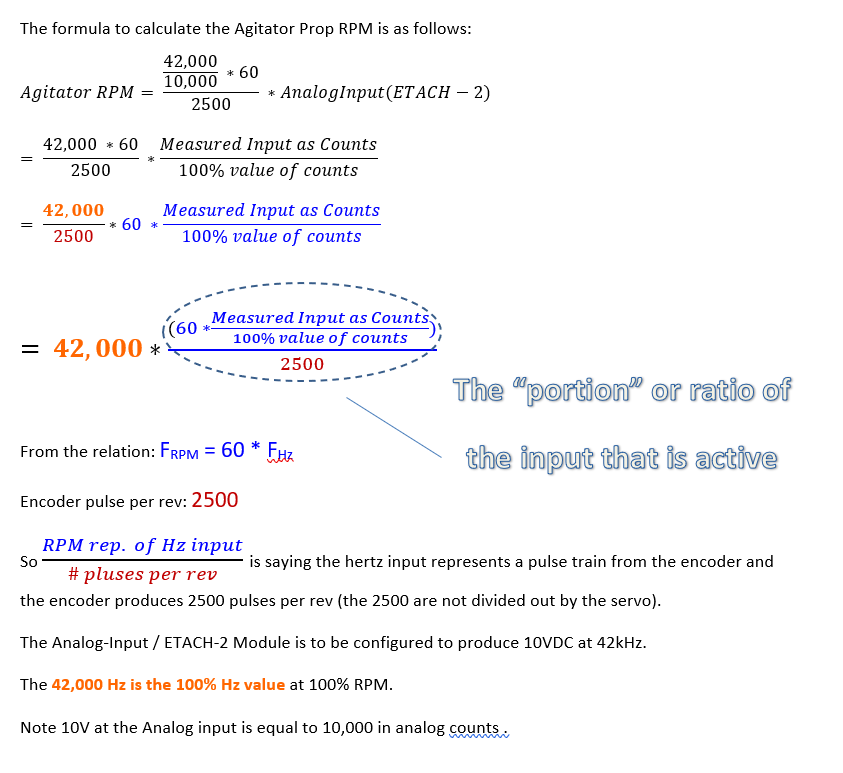

Generic Servo Project Notes

Generic Servo Project Notes

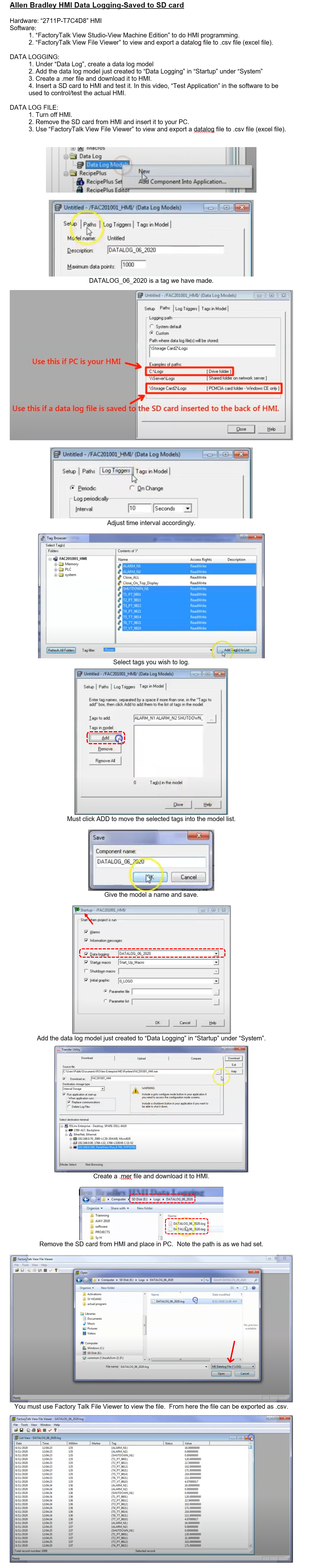

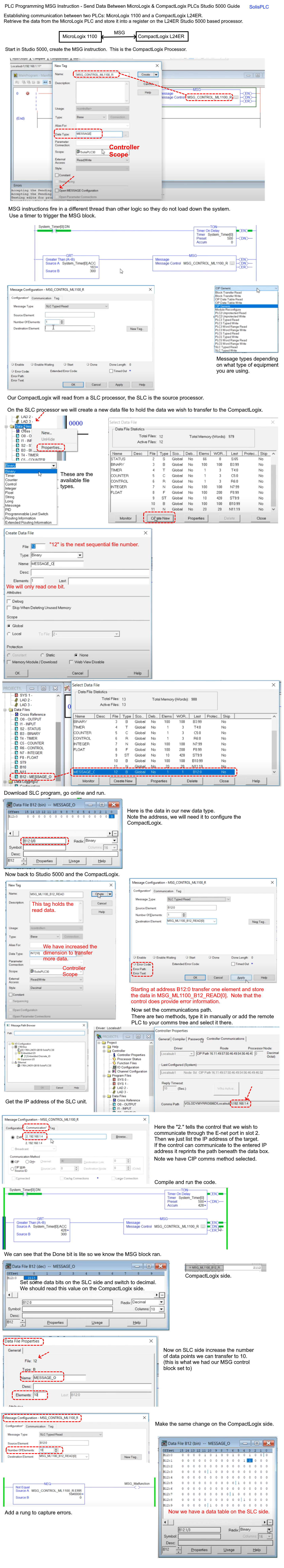

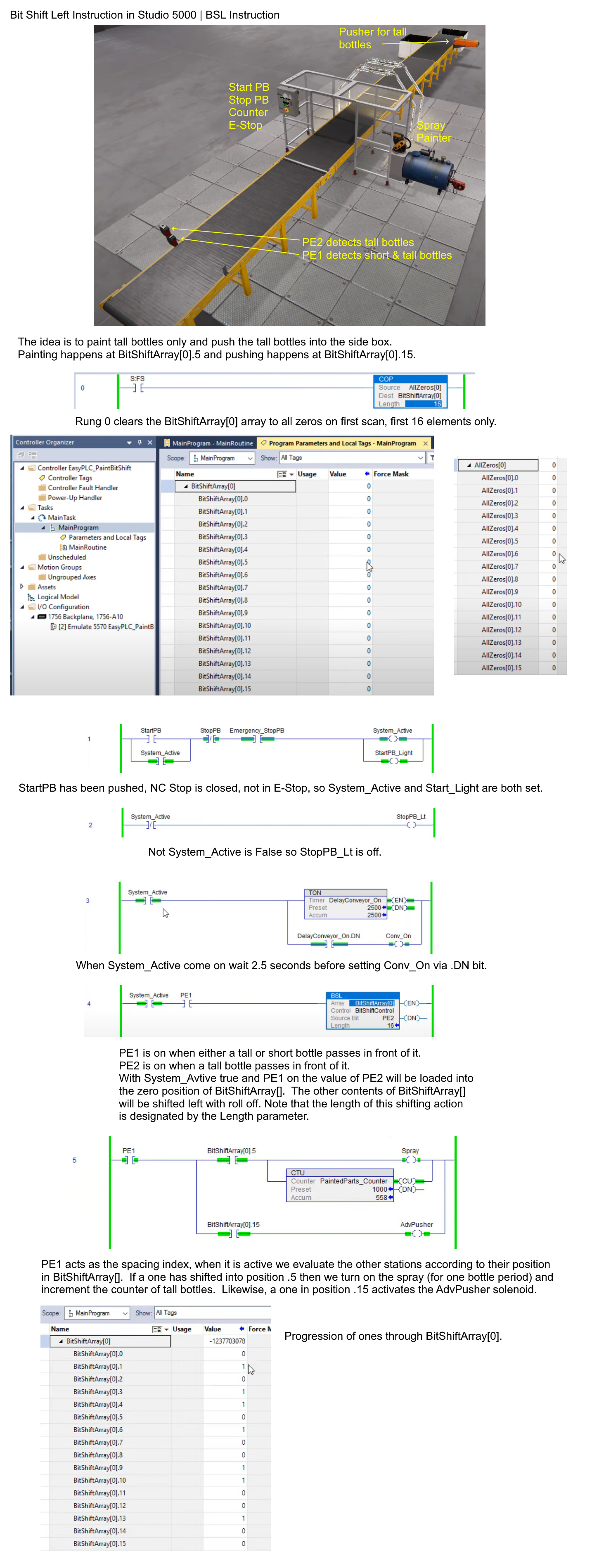

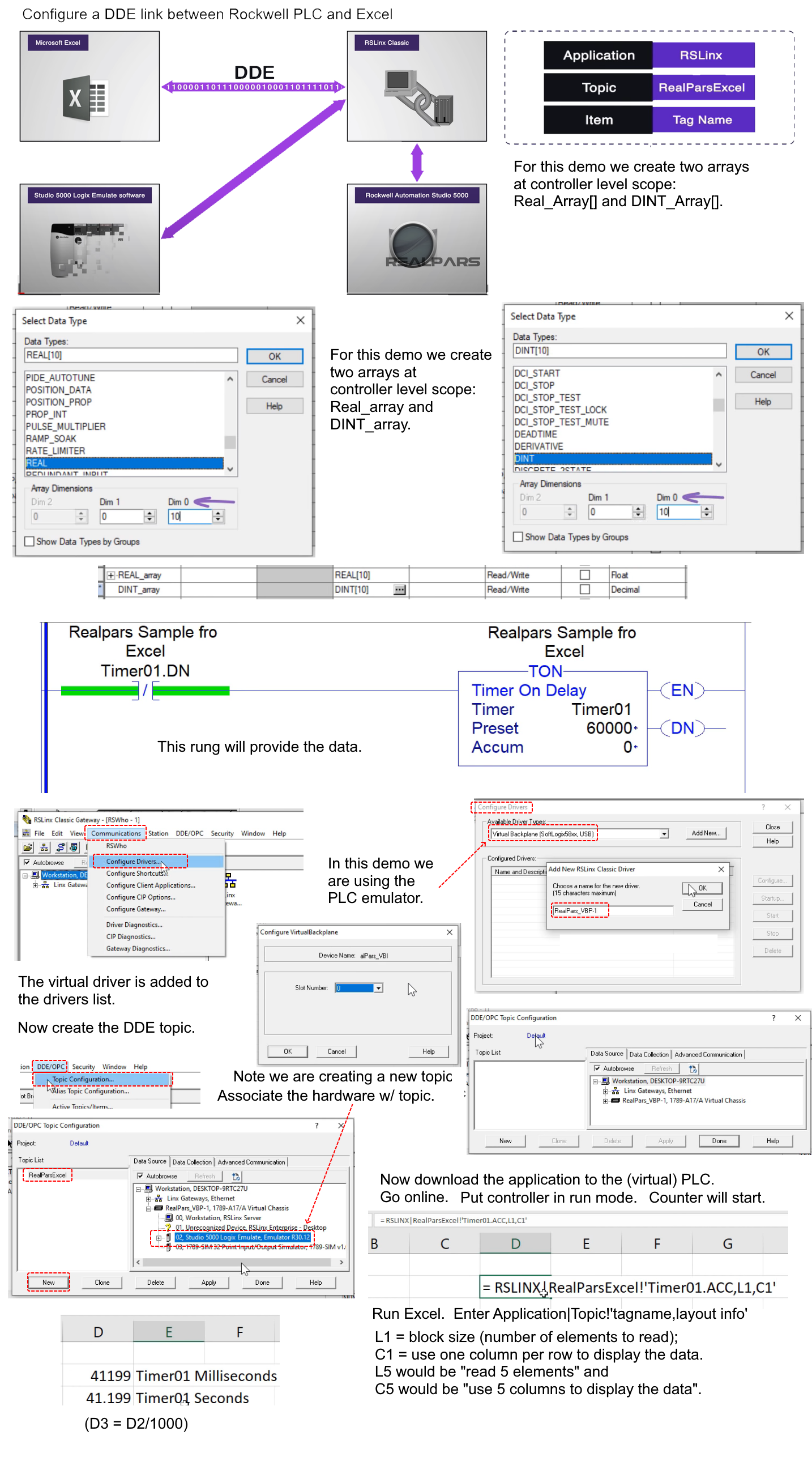

DDE: PLC to Excel

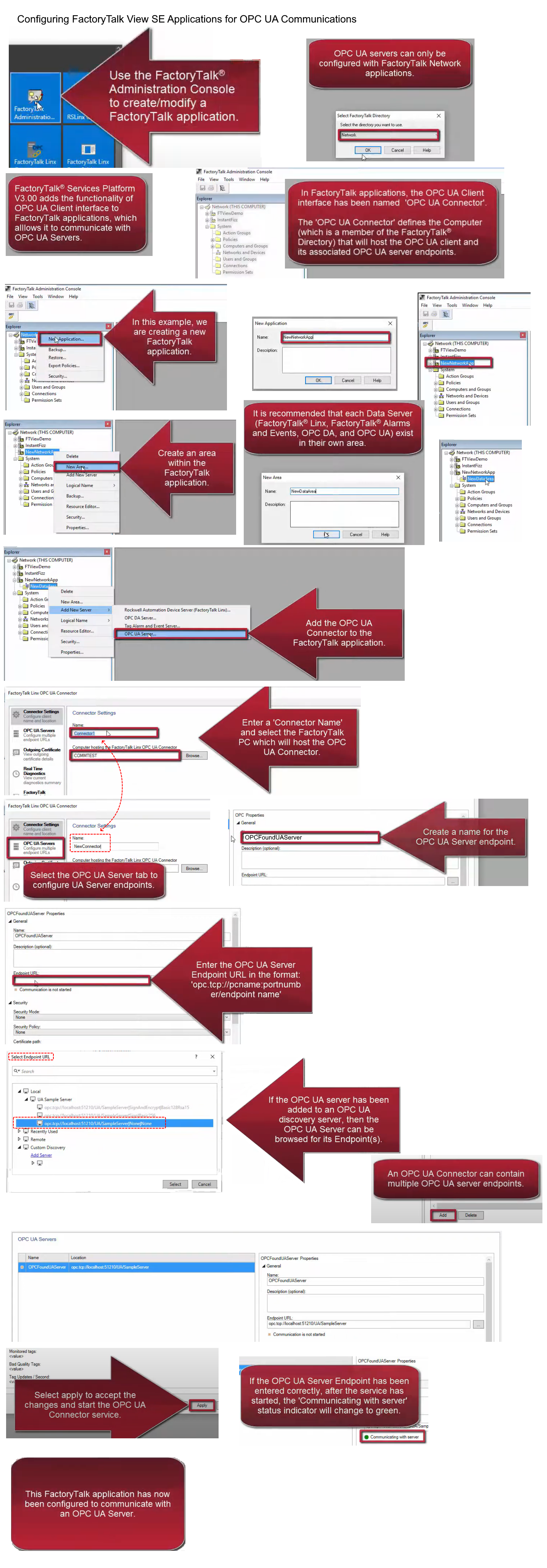

DDE: PLC to Excel FTV SE to OPC-UA Server

FTV SE to OPC-UA Server

.png)